PoleMax MP3 Channel Reinforcement | Morgantown, West Virginia

PoleMax MP3 Channel Reinforcement | Morgantown, West Virginia

Project Description:

This monopole is located in Morgantown, WV and provides cell coverage for the greater Philadelphia area. This project focused on providing a non-welded shaft solution as well as a base plate upgrade for the modification and placement of new antennas.

Aero Solutions Role:

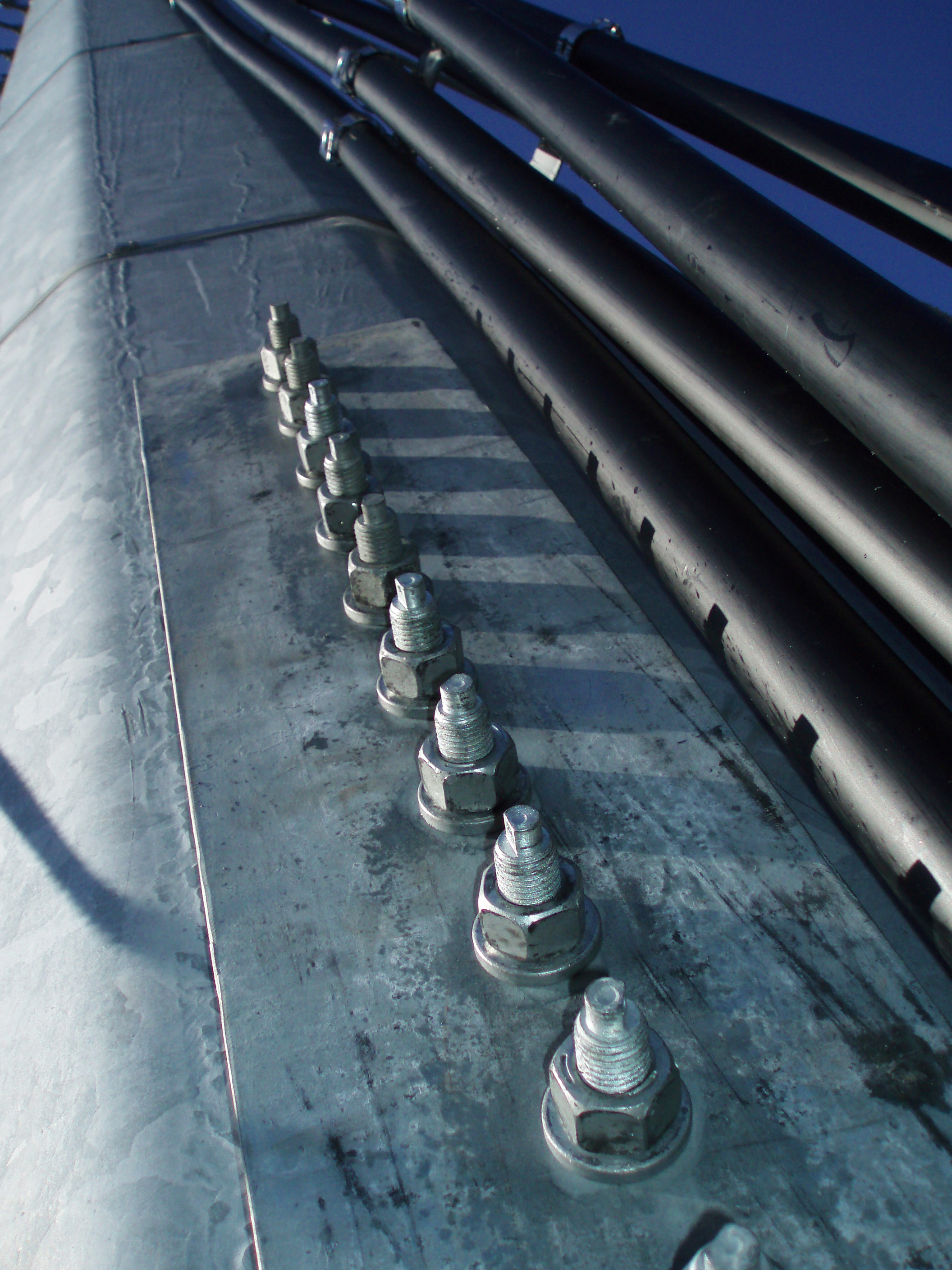

Aero Solutions provided a design/build solution to bring the tower into TIA compliance with the new antenna loading using non-welded reinforcing elements. Due to the new wind area of the antennas, sections of the monopole were overstressed and required reinforcement using the PoleMax® MP3 channels. Bolted channels were installed symmetrically around the pole from 0 – 109 feet. The base plate upgrade consisted of the installation of 3 new anchor rods with brackets, gussets, foot pads as well as transition stiffeners with bearing plates. Aero Solutions managed the engineering, drawings, material fabrication, installation and closeout of the project.

Technical Description:

Tower Type: Monopole

Tower Height: 150 feet

Client: Crown Castle International